Ke ʻenehana hana ʻilikai e ʻike ʻia ai ka oka a ke alumini

Ke ʻenehana hana ʻilikai e ʻike ʻia ai ka oka a ke alumini

|

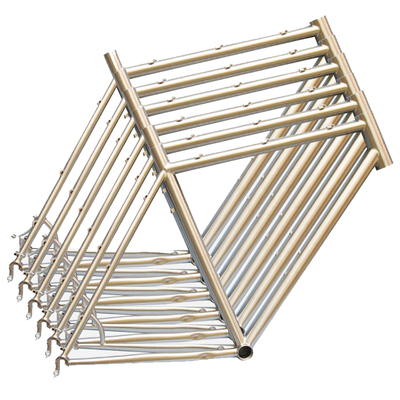

He nui nā mea maikaʻi o ka Aluminika e like me ka haʻahaʻa haʻahaʻa, ikaika kikoʻī kiʻekiʻe, kūpaʻa kūpaʻa maikaʻi, kiʻekiʻe uila a me ka conductivity thermal, weldability, plasticity maikaʻi, maʻalahi a me ka hana ʻana, a me nā waiwai hoʻonaninani ʻili maikaʻi. Hana ʻia ka alumini alumini me ka alumini maʻemaʻe ma ka hoʻohui ʻana i kekahi mau mea hoʻohui. ʻOi aku ka maikaʻi o ka alumini alumini ma mua o ka alumini maʻemaʻe. ʻOi aku ka maikaʻi o ke kino a me ka mechanical. Ma muli o ke ʻano hana o ke alumini, hiki ke hana maʻalahi i kahi kiʻi ʻoniʻoni amorphous i ka lewa, e hana ana i ke kūpaʻa kūpikipiki ʻoi aku ka maikaʻi i ka lewa, akā ʻo ka mānoanoa kiʻi ʻoniʻoni ma kahi o 4nm wale nō, a he palalā, lahilahi a lahilahi ke ʻano. Porous, haʻahaʻa paʻakikī, ʻaʻahu maikaʻi ʻole, a me ka ikaika mechanical haʻahaʻa, no laila pono e uhi lima i ka ʻili alumini me kahi kiʻiʻoniʻoni e hoʻokō i ke kumu o ka pale. Hiki ke hoʻokō pinepine ʻia e ka mālama ʻana i ka oxidation, electroplating, a me ka uhi waho. |

1 Lapaʻau ʻana

ʻO ka hoʻomaʻamaʻa oxidation ka nui o ka anodic oxidation, oxidation chemical, a me ka micro-arc oxidation. Xu Lingyun et al. Ua aʻo ʻo [1] i nā waiwai mechanical a me ke kūpaʻa ʻana o ke alumini alumini A356 ma ka hana ʻana i ʻekolu ʻokoʻa ka lāʻau maʻamaus: hoʻokahe kemika, anodization a me ka micro-arc oxidation. Ma o ka ʻenehana SEM, komo i ka hoʻāʻo a me ka hoʻowali kūpaʻa kūpale, ka pae o ka morphology, ka mānoanoa o ka oxide, pale i ka pale a me ke kūpaʻa o ke kinikini aluminika ma hope o ʻekolu ka lāʻau maʻamaus ua kālailai ʻia a hoʻohālikelike i nā kikoʻī. Hōʻike nā hopena ma hope o nā ʻokoʻa ka lāʻau maʻamaus, hiki i ka ʻili alumina aluminika ke hana i nā kiʻiʻoniʻoni oxide o nā mānoanoa like ʻole, ʻoi aku ka maikaʻi o ka paʻakikī o ka ʻili a me ke kūpaʻa ʻana, a ua hoʻomaikaʻi ʻia ke kūpaʻa corrosion o ka alloy i nā pae like ʻole. Ma ke ʻano o ka hana holoʻokoʻa, ʻoi aku ka maikaʻi o ka micro-arc oxidation ma mua o ka anodic oxidation, a ʻoi aku ka maikaʻi o ka oxidation anodic ma mua o ka oxidation kemika.

1.1 Anodizing

Kapa ʻia ʻo Anodizing i ka electrolytic oxidation, ʻo ia ka mea maʻamau i ka mālama ʻana i ka electrochemical oxidation. Hoʻohana ia i nā alumini alumini a me nā alumini e like me nā anodes i loko o ke kelepona electrolytic, a ua hoʻokumu ʻia kahi kiʻi oxide (ʻoi aku ka nui o Al 2 O 3) ma ka ʻili alumini ma hope o ka mana. ʻO ke kiʻi ʻoniʻoni i loaʻa e ka anodic oxidation he kūpaʻa maikaʻi ka corrosion, ka hana paʻa a me ka hoʻolaha maʻalahi. ʻO ia ke kumu maʻamau a me ka maʻamau o ka mālama ʻana i ka papa no ka aluminika a me ke alumini i kēia manawa i koʻu ʻāina. He nui nā hiʻohiʻona o ke kiʻi ʻoniʻoni anodic: ʻo ka papa pale o ke kiʻi oxide he paʻakikī kiʻekiʻe, ʻoi aku ka maikaʻi o ka pale ʻana, ka pale ʻana i ka corrosion maikaʻi, ka mea insulation maikaʻi, ke kūpaʻa kemika kiʻekiʻe, a hiki ke hoʻohana ʻia e like me ke kiʻi kumu no ka uhi ʻana; ʻO ka kiʻiʻoniʻoni oxide he nui nā pinholes a hiki ke hoʻohana ʻia Hoʻohana ʻia i nā kala like ʻole a me nā kala e hoʻonui ai i ka hana hoʻonaninani o ka ʻili alumini; he haʻahaʻa loa ka conductivity thermal o ke kiʻiʻoniʻoni oxide, a he mea pale wela maikaʻi a me ka pale pale wela. Eia nō naʻe, hoʻohana pinepine ka hoʻoheheʻe anodic o ke alumini a me nā alumini alumini i ka chromate ma ke ʻano he oxidant, kahi e kumu ai ka haumia o ka nohona.

I ka noiʻi o kēia manawa e pili ana i ka anodizing o nā alumini a me nā alumini alumini, ua uku ʻia ka nānā ʻana i ka hoʻohana ʻana i nā hiʻohiʻona o kekahi mau ion metala e hoʻomaikaʻi i nā waiwai o nā alumini a me nā alumini alumini. No ka laʻana, ua hoʻohana ʻo Tian Lianpeng [2] i ka ʻenehana implantation ion e inject titanium ma ka ʻili o ke alumini alumini, a laila hana hou i ka anodization no ka loaʻa ʻana o kahi alumini-titanium composite anodized film layer, i hana i ka ili o ka anodized film ʻoi aku ka palahalaha a me ka lole. , a hoʻomaikaʻi i ka anodization o ka alumini alumini. Ka mānoanoa o ke kiʻi ʻoniʻoni; Hiki i ka titanium implantation ke hoʻomaikaʻi maikaʻi i ka pale ʻana o ka alumini anodic oxide kiʻi i loko o ka waikawa a me ka alkaline NaCl solutions, akā ʻaʻole ia e pili i ke ʻano amorphous o ka alumini anodic oxide film. ʻO ka hoʻokomo ʻana i ka Nickel ion e hana i ka ʻili o ka ʻili a me ka morphology o ke kiʻi ʻoniʻoni anodic oxide alumini i ʻoi aku ka paʻa a me ke ʻano like. Aia ka nickel injected ma ke ʻano o ka nickel metallic a me ka nickel oxide i loko o ke kiʻi ʻoniʻoni anodic oxide alumini.

1.2 Kemikini oxidation

ʻO ka oxidation kemika e pili ana i ke ʻano o ka uhi ʻana o kahi ʻili alumini maʻemaʻe e launa pū me ka oxygen i loko o kahi hopena oxidizing ma o ka hana kemika ma lalo o kekahi mau kūlana wela e hana i kahi kiʻiʻoniʻoni oxide. Nui a hewahewa nā ʻano hana hoʻoheheʻe kemika no ka hoʻopili ʻana o ka aluminika a me ka aluminika, e like me ke ʻano o ka hopena

Hiki ke hoʻokaʻawale ʻia i ka alkaline a me ka acidic. E like me ke ʻano o ke kiʻiʻoniʻoni, hiki ke hoʻokaʻawale ʻia i ke kiʻiʻoniʻoni oxide, phosphate film, chromate film a me chromic acid-phosphate film. ʻO ke kiʻi ʻoniʻoni i loaʻa ʻia e ka mea hoʻowali ʻino o ka aluminika a me nā ʻāpana alumini i loaʻa ka mānoanoa ma kahi o 0.5 ~ 4μm. Loaʻa iā ia ke kūpaʻa ʻaʻahu maikaʻi ʻole a me ke kūpaʻa corrosion haʻahaʻa ma mua o ke kiʻi ʻoniʻoni anodic oxide. ʻAʻole kūpono ia e hoʻohana wale ʻia, akā loaʻa iā ia ke kūpaʻa corrosion a me nā waiwai kino maikaʻi. ʻO ka hiki ke loaʻa i ka absorption kahi primer maikaʻi no ka pena ʻana. ʻO ka pena ma hope o ka hoʻoheheʻe ʻia ʻana o ka alumini a me ke alumini alumini hiki ke hoʻomaikaʻi nui i ka ikaika paʻa ma waena o ka substrate a me ka uhi ʻana, a hoʻonui i ka pale ʻana o ka alumini [3].

1.3 Micro-arc oxidation ala

ʻIke ʻia ka ʻenehana micro-arc oxidation ʻo ke ʻenehana hoʻowaiwai micro-plasma a i ʻole he ʻenehana neʻe anode spark, kahi ʻano ulu ulu ma o ka hoʻokuʻu micro-plasma ma ka papa o ka mea kila a me nā mea pili. ʻOkiʻi

ʻO ka ʻenehana hou o ka membrane keramika. ʻO ke kiʻi ʻoniʻoni i hoʻokumu ʻia e kēia ʻenehana he ikaika paʻa paʻa me ka substrate, paakiki kiʻekiʻe, ʻaʻaʻa pale, kūpaʻa kūpale, kūpale kūwewe kūwewe kiʻekiʻe, hoʻoweliweli uila maikaʻi o ke kiʻi ʻoniʻoni, a me ka voltage breakdown kiʻekiʻe. ʻAʻole wale ia, hoʻohana ka ʻenehana i ka hoʻomehana hoʻomehana holomua o ka hoʻomehana ʻana o ka micro plasma arc me ka kiʻekiʻe o ka ikehu kiʻekiʻe loa, ʻaʻole pili ka hanana matrix, a ʻaʻole paʻakikī ka hana, ʻaʻole kumu i ka haumia o ke kaiapuni. He mea hoʻohiki hou ʻenehana lapaʻau ʻili. Ke lilo nei ia i wahi pumehana noiʻi i ke kahua o ka ʻenehana ʻenehana ʻilikai pae honua. Zhang Juguo et al.

hoʻohana alumini mīkini alloy LY12 e like me ka mea ho'āʻo, hoʻohana i ka MAO240/750 micro-arc oxidation lako, TT260 mānoanoa ana a me AMARY-1000B scanning electron microscope e aʻo i ka hopena o ka arc voltage, ka nui o kēia manawa a me ka manawa oxidation ma ka papa ceramic. Ka hopena hana. Ma o ke kaʻina hana o ka alumini alumini micro-arc oxidation kaʻina hana hoʻokolohua me Na 2 SiO 3 electrolyte, ke kānāwai ulu o ka ceramic oxide film i ka wā o ka micro-arc oxidation kaʻina hana a me ka mana o nā ʻano electrolyte ʻokoʻa a me ka noʻonoʻo ʻana i ka maikaʻi o ka ceramic oxide. aʻo ʻia ke kiʻiʻoniʻoni. ʻO ka micro-arc oxidation o ka ʻili alumini alumini he kaʻina hana paʻakikī loa, me ka hoʻokumu ʻana o ka electrochemical o ke kiʻi oxide mua, a me ka haki ʻana o ka kiʻi ceramic, e komo pū ana nā hopena kino o ka thermochemistry, electrochemistry, māmā, uila, a me ka wela. .

Hoʻopili ʻia kahi kaʻina hana e ka mea o ka substrate ponoʻī, nā ʻāpana lako mana, a me nā ʻāpana electrolyte, a he paʻakikī ke nānā ʻana ma ka pūnaewele, e lawe mai ana i nā pilikia i ka noiʻi theoretical. No laila, i kēia manawa, ʻaʻohe kumu hoʻohālike e hiki ke wehewehe pono i nā ʻano hoʻokolohua like ʻole, a ʻo ka noiʻi ʻana i kāna mīkini e pono ai ka ʻimi hou a me ka hoʻomaikaʻi ʻana.

2 Hoʻohui uila a me ka plating kemika

ʻO ka Electroplating ka waiho ʻana i kahi papa o ka uhi metala ʻē aʻe ma luna o ka ʻili o ka aluminika a me ke alumini alumini e nā ʻano kemika a i ʻole nā mea electrochemical, hiki ke hoʻololi i nā waiwai kino a i ʻole kemika o ka ʻili alumini. ʻili

Conductivity; hiki i ke keleawe, nickel a i ʻole ke plating ke hoʻomaikaʻi i ka weldability o ke kinikini aluminika; a hiki ke hoʻomaikaʻi i ka lubricity o ka alumini alumini a i ʻole ka alumini-tin alloy; e hoʻomaikaʻi maʻamau i ka paʻakikī o ka ʻili a me ke kūpaʻa ʻana o ke alumini alumini me ka chromium plating a i ʻole ka nickel plating; Hiki i ka Chrome a i ʻole ka nickel plating ke hoʻomaikaʻi i kona hoʻonaninani. Hiki ke electrolyzed ka aluminika i ka electrolyte e hana i kahi uhi, akā maʻalahi ka uhi ʻana i ka uhi. No ka hoʻoponopono ʻana i kēia pilikia, hiki ke waiho ʻia ka aluminika a hoʻopaʻa ʻia i loko o kahi hopena wai i loaʻa i kahi pūhui zinc. ʻO ka papa immersion zinc ka mea e hoʻopili ai i ka aluminika a me kāna matrix alloy a me nā uhi hope. Alahaka nui, Feng Shaobin et al. [7] ua aʻo i ka palapala noi a me ka hana o ka zinc immersion layer ma ka papa kuhumu aluminika, a hoʻolauna i ka ʻenehana hou a me ka noi o ke kaʻina immersion zinc. ʻO ka electroplating ma hope o ka hoʻokomo ʻana i ka zinc hiki ke hana i kahi kiʻiʻoniʻoni porous lahilahi ma ka ʻili o ka alumini a laila electroplating.

ʻO ka plating electroless e pili ana i kahi ʻenehana hana kiʻi ʻoniʻoni kahi i waiho ʻia ai kahi uhi kila i kahi papa hao e kahi hopena kemikal autocatalytic i loko o kahi hopena e noho pū ana me ka paʻakai metala a me kahi mea hōʻemi. I waena o lākou, ʻo ka mea i hoʻohana nui ʻia he electroless Ni-P alloy plating. Hoʻohālikelike ʻia me ke kaʻina hana uila, a plating electroless a

ʻO kahi kaʻina hoʻohaʻahaʻa haʻahaʻa loa, ʻo ke kinikini Ni-P i loaʻa he pani maikaʻi no ka plating chromium. Eia nō naʻe, nui nā lako hana no ka plating electroless, nui ka hoʻohana ʻana i nā mea waiwai, lōʻihi ka manawa hana, paʻakikī nā kaʻina hana, a paʻakikī ke hōʻoia i ka maikaʻi o nā ʻāpana plating. ʻO kahi laʻana, Feng Liming et al. Ua aʻo ʻo [8] i kahi kikoʻī hana no ka hoʻopili ʻana o ka electroless nickel-phosphorus e hoʻopili wale ana i nā kaʻina hana pretreatment e like me ka degreasing, immersion zinc, a me ka holoi wai e pili ana i ka hoʻohui o 6063 aluminika. Hōʻike nā hopena hoʻokolohua he maʻalahi ke kaʻina hana, ʻo ka papa nickel electroless he kiʻekiʻe kiʻekiʻe, ka ikaika hoʻopaʻa ikaika, ka waihoʻoluʻu paʻa, ka uhi paʻa, ka maʻi phosphorus ma waena o 10% a me 12%, a ʻo ka paʻakikī o ka mokuʻāina plating hiki ke piʻi aku ma mua o 500HV, ʻoi aku ke kiʻekiʻe ma mua o ka anode. Pākuʻi ʻoka [8]. Ma waho aʻe o ka electroless Ni-P alloy plating, aia kekahi mau alloys ʻē aʻe, e like me ka alloy Ni-Co-P i aʻo ʻia e Yang Erbing [9]. He coercivity kiʻekiʻe ke kiʻi ʻoniʻoni, remanence liʻiliʻi a me ka hoʻohuli electromagnetic maikaʻi loa. ʻO nā hiʻohiʻona, hiki ke hoʻohana ʻia i nā pā kiʻekiʻe a me nā māla ʻē aʻe, me ka plating electroless

Hiki i ke ala Ni-Co-P ke loaʻa i ka mānoanoa like ʻole a me ke kiʻi ʻoniʻoni magnetic ma luna o kekahi substrate ʻano paʻakikī, a loaʻa iā ia nā pōmaikaʻi o ka hoʻokele waiwai, ka hoʻohana haʻahaʻa haʻahaʻa a me ka hana maʻalahi.

3 Ka uhi ʻana o ka ʻili

3.1 Hoʻopili laser

I nā makahiki i hala aku nei, ʻo ka hoʻohana ʻana o nā kukuna kukuna ikaika kiʻekiʻe no ka hoʻomaʻamaʻa ʻana i ka laser ma nā ʻili alumini i hiki ke hoʻomaikaʻi maikaʻi i ka paʻakikī a ʻaʻa i ke kūpaʻa o nā ʻāpana alumini a me aluminika. No ka laʻana, hoʻohana ʻia kahi laser 5kW CO 2 e hoʻopaʻa i ka uhi plasma Ni-WC ma ka ʻili o ka ZA111 alloy. Loaʻa ka paʻakikī paʻakikī ka laser fusion layer i loaʻa, a ʻo kona lubrication, ʻaʻahu a me ke kūpaʻa abrasion ʻo 1.75 mau manawa ia o ka uhi ʻehu me ka ʻole o ka hoʻomaʻamaʻa laser a me 2.83 mau manawa o ka matrix al-Si alloy. Ua hoʻohana ʻo Zhao Yong [11] i nā kukuna CO 2 i nā ʻāpana alumini a me nā ʻāpana alumini

Hoʻopili ʻia me ka Y a me ka Y-Al pauka, ua uhi ʻia ka pauka ma ka ʻili o ka substrate e ke ʻano o ka uhi ʻana i ka pauka preset, pale ʻia ka ʻauʻau laser e argon, a me kahi nui o CaF 2, LiF a me MgF 2. i hoʻohui ʻia ma ke ʻano he mea hana slag Ma lalo o kekahi mau ʻāpana kaʻina hana hoʻopaʻa laser, hiki ke loaʻa i kahi ʻaʻahu a me ka hoʻomau ʻana o ka uhi paʻa me kahi interface metallurgical. Ua hoʻohana ʻo Lu Weixin [12] i ka laser CO 2 no ka hoʻomākaukau ʻana i ka uhi pauka Al-Si, ka uhi pauka Al-Si+SiC a me ka uhi ʻana o ka pauka Al-Si+Al 2 O 3 ma ka substrate alloy alumini ma ke ʻano hoʻopaʻa laser. , Al keleawe pauda uhi. ʻO Zhang Song et al. [13] hoʻohana i ka laser 2 k W mau Nd:YAG ma AA6 0 6 1 alumini.

ʻO ka ʻāpana o ke kinikini he cladding kukuna me ka paukū pālolo SiC, a hiki ke hoʻomākaukau ʻia ka papa metala i hoʻohui ʻia (MMC) ma ka ʻili o ke alumini aluminika ma o ka mālama hoʻoheheʻe laser.

3.2 ʻO ka uhi ʻana i ka hui

ʻO ka uhi hoʻohuihui alumini lubricating ponoʻī me ka anti-friction maikaʻi loa a me nā waiwai kūʻē i ka ʻaʻahu he mau noi maikaʻi loa i ka ʻenekinia, ʻoi aku hoʻi ma ke kahua o ka ʻenehana ʻoki. No laila, ʻo ka porous alumina membrane me kahi hoʻolālā pore matrix ua loaʻa hou aʻe ka nānā ʻana mai nā poʻe. E noʻonoʻo, ua lilo ka ʻenehana hoʻohuihui alumini alumini i hoʻokahi o nā wahi wela noiʻi o kēia manawa. Ua aʻo ʻo Qu Zhijian [14] i ka alumini a me ka 6063 alumini alumini hoʻohui i ka ʻenehana hoʻoheheʻe ponoʻī. ʻO ke kaʻina hana nui e hana i ka anodization paʻakikī ma ka alumini a me ka 6063 alumini alumini, a laila e hoʻohana i ke ʻano wela wela e hoʻokomo i nā ʻāpana PTFE i loko o nā pores kiʻiʻoniʻoni oxide. A ʻo ka ʻili, ma hope o ka hoʻomaʻamaʻa ʻana i ka wela wela, ua hoʻokumu ʻia kahi uhi hoʻohui. Ua noiʻi ʻo Li Zhenfang [15] i kahi kaʻina hana hou e hui pū ana i ka uhi pena resin a me ke kaʻina hana electroplating ma ka ʻili o nā huila alumini i hoʻohana ʻia i nā kaʻa. ʻO ka manawa hoʻāʻo CASS he 66 mau hola, ʻo ka blistering rate he ≤3%, ka nui o ka leakage keleawe he ≤3%, hoʻemi ʻia ke koena ikaika e 10 ~ 20g, a he nani ke ʻano o ka pena resin a me ka uhi metala.

4 Nā ʻano hana ʻē aʻe

4.1 Ion implantation ala

Hoʻohana ke ʻano implantation ion i nā kaola ion kiʻekiʻe e hoʻopaʻa i ka pahu i loko o kahi mokuʻāina. ʻAneʻane hiki ke hoʻokō ʻia kekahi implantation ion. Hoʻokuʻu ʻia nā ion i hoʻokomo ʻia a waiho ʻia ma ke kūlana pani a i ʻole ke kūlana ākea o ka hopena paʻa e hana i kahi papa ʻili ʻole. Aluminum huila

Hoʻomaikaʻi ʻia ka paʻakikī o ka ʻili, ka pale ʻana a me ka pale ʻana i ka corrosion. Hoʻopili ka Magnetron titanium maemae i ukali ʻia e ka PB11 nitrogen / carbon implantation hiki ke hoʻomaikaʻi maikaʻi i ka microhardness o kahi i hoʻololi ʻia. Hoʻokomo ʻia ka sputter Magnetron me ka injection nitrogen e hoʻonui i ka paʻakikī o ka substrate mai 180HV a i 281.4HV. Hiki ke hoʻonui i ka 342HV [16]. ʻO Magnetron sputtering titanium maʻemaʻe i ukali ʻia e PB11 nitrogen/carbon implantation hiki ke hoʻomaikaʻi nui i ka microhardness o ka ʻili i hoʻololi ʻia. Liao Jiaxuan et al. [17] i hana i ka hoʻopili ʻana o ka titanium, nitrogen, a me carbon ma ke kumu o ka implantation ion i hoʻokumu ʻia me ka plasma o LY12 aluminika, a loaʻa nā hopena hoʻololi nui. Ua alakaʻi ʻo Zhang Shengtao lāua ʻo Huang Zongqing o ke Kulanui ʻo Chongqing [18] i ka hoʻokomo ʻana i ka ion titanium ma ka alumini alumini. Ua hōʻike nā hopena i ka hoʻokomo ʻana o ka ion titanium ma ka ʻili o ke alumini alumini he ala maikaʻi e hoʻomaikaʻi ai i kona kūʻē ʻana i ka chloride ion corrosion, a hiki ke hoʻomaikaʻi i ka hiki o ke alumini alumini e kūʻē i ka chloride ion corrosion. Hoʻonui i ka laulima passivation o ke alumini i loko o NaCl a me nā hopena ʻē aʻe, a e hoʻoliʻiliʻi i ka nui a me ka nui o nā pores corrosion i ʻino ʻia e nā ions chloride.

4.2 ʻO ka uhi hoʻololi ʻana o ka honua

Hiki ke hoʻomaikaʻi i ka pale ʻana i ka corrosion o nā alumini alumini ka hoʻololi ʻana o ka honua, a ʻo ke kaʻina ka mea nui i ka hoʻomaʻamaʻa kemika. Pono ka honua laha i ka alumini anodic oxidation. Hoʻonui ia i ka hiki o ka alumini alumini e ʻae i ka polarization a i ka manawa like e hoʻomaikaʻi i ke kūpaʻa corrosion o ke kiʻi oxide. No laila, hoʻohana ʻia nā ʻāina rare ma

ʻO ka hoʻomaʻamaʻa ʻana i ka ʻili alumini alumini he mau manaʻo hoʻomohala maikaʻi [19]. Shi Tie et al. [20] ua aʻo i ke kaʻina hana o ka hoʻokumu ʻana i kahi kiʻi paʻakai cerium paʻakai ma ka ʻili o ka popo-hōʻoia alumini LF21 e ka electrolytic deposition. Ua hoʻohana ʻia ka hoʻokolohua orthogonal e hoʻopaʻa i ka mana o nā mea e pili ana i ke kaʻina hana ʻoniʻoni a loaʻa nā pae loea ʻoi loa. Hōʻike nā hualoaʻa ua ālai ʻia ke kaʻina hana corrosion anodic o ka alumini rust-proof ma hope o ka mālama ʻana i ka electrolytic deposition o ka honua hoʻololi kiʻi ʻoniʻoni, ua hoʻomaikaʻi maikaʻi ʻia kona kūpaʻa corrosion, a ua hoʻomaikaʻi nui ʻia ka hydrophilicity. ʻO Zhu Liping et al. [21] hoʻohana i ka microscopy electron scanning (SEM), spectroscopy ikehu (EMS) a me nā ʻano hoʻāʻo ʻehu paʻakai e hoʻopaʻa i ka ʻōnaehana i ke ʻano, ka haku ʻana a me ka compactness o ke kinikini aluminika e ʻike pinepine ʻia i ka honua cerium paʻakai hoʻohuli paʻakai ma kāna kūpaʻa kūpaʻa. Hoʻohuli manaʻo. Hōʻike nā hopena noiʻi i ka ʻikena cerium honua laha ʻole i ka kiʻi ʻoniʻoni ke kāohi i ka hana ʻinoʻino pitting o ke kinikini alumina a hoʻomaikaʻi maikaʻi i kāna kūpaʻa kūpaʻa.

He mea koʻikoʻi ka pale ʻana i ka corrosion. I kēia mau lā, aia nā ʻano hana lapaʻau like ʻole o ka alumini a me nā alumini alumini, a ʻoi aku ka ikaika a me ka ikaika o kā lākou hana, hiki ke hoʻokō i nā pono o ka alumini a me nā alumini alumini i ke ola, ka lāʻau lapaʻau, ʻenekinia, aerospace, instrumentation, electronic appliances, food and ʻoihana māmā, etc. Pono. I ka wā e hiki mai ana, e maʻalahi ka mālama ʻana o ka alumini a me nā alumini alumini i ke kaʻina hana, kūpaʻa i ka maikaʻi, ka nui, ka mālama ʻana i ka ikehu, a me ke aloha kaiapuni.

Hoʻomohala kuhikuhi. He block copolymer o ka ester-amide hoʻololi hoʻololi me ke kiʻekiʻe o ka hoʻololi ʻana. Korshak et al. [11] hōʻike i ka wā e hoʻohana ʻia ai ka 1% PbO 2 a i ʻole 2% PbO 2 ma ke ʻano he catalyst a hoʻomehana ʻia ma 260 degere no 3-8 mau hola, e hana pū ʻia ka hopena ma waena o ka polyester a me ka polyamide. ʻO ka hopena hoʻololi ester-amide kekahi mana i ka hoʻohālikelike o ka ʻōnaehana hui. Xie Xiaolin, Li Ruixia, etc. [12] me ka hoʻohana ʻana i ka hopena

ʻO ke ʻano, ka hui ʻana o ka mīkini maʻalahi (ke ʻano hoʻoheheʻe 1) a me ke ʻano o ka ester-amide exchange reaction reaction blending method (melting method) e hoʻohui i ka PET a me PA66, systematically DSC analysis, a me ka hoʻohālikelike ʻana o ka PET/PA66 blending system Ua kūkākūkā ʻia ke kāne i kekahi ʻano. Hōʻike nā hopena i ka ʻōnaehana hui ʻana o ka PET/PA66 he ʻōnaehana thermodynamically incompatible, a ʻoi aku ka maikaʻi o ka hui ʻana o ka hui hoʻoheheʻe ʻoi aku ka maikaʻi ma mua o ka hui ʻana o ka hopena, a ʻo ka copolymer poloka i hana ʻia e ka hui PET/PA66 ua kūpono me ʻelua. ua hoʻomaikaʻi ʻia; me ka hoʻonui ʻana o ka waihona PA66, ua emi ka helu heheʻe o ka hui. ʻO ka PET/PA66 block copolymer i hoʻokumu ʻia e ka hopena e hoʻonui i ka hopena nucleation o PA66 ma ka PET phase crystallization, ka hopena i ka hoʻoheheʻe ʻana ʻO ka crystallinity o ka hui Farani ʻoi aku ka kiʻekiʻe ma mua o ke ʻano hoʻoheheʻe 1 hui. ʻO Zhu Hong et al. [13] hoʻohana i ka p-toluenesulfonic acid (TsOH) a me nā mea hoʻopili titanate ma ke ʻano he catalysts no ka hoʻololi ʻana o ka ester-amide ma waena o Nylon-6 a me PET no ka hoʻokō ʻana i ka hui ʻana o nā hui ʻo Nylon-6/PET. ʻO ke kumu o ka nānā ʻana i nā hualoaʻa electron microscope e hōʻike ana i ka hui ʻana o Nylon-6/PET he ʻōnaehana hoʻokaʻawale ʻāpana crystalline me ka maikaʻi ʻole. Hoʻohui i ka p-toluenesulfonic acid a me ka titanate coupling agent ma ke ʻano he mea hoʻoikaika e hoʻoikaika i ka hoʻokumu ʻana o ka poloka in-situ. . Kōkua nā mea ʻelua i ka hoʻomaikaʻi ʻana i ka hoʻohālikelike ʻana o ka hui ʻana a hoʻonui i ka hoʻopili interfacial o nā pae ʻelua.

Nānā 2

I nā makahiki i hala iho nei, ua hana nā mea noiʻi kūloko i nā hana noiʻi he nui no ka hui ʻana o ka polyamide / polyester a ua loaʻa i nā hopena maikaʻi he nui, e kau ana i kahi kumu maikaʻi no ka noiʻi e hiki mai ana ma kēia wahi. I kēia manawa, ʻo ka mea e pono e nānā ʻia ʻo ka hoʻolaha ʻana i ka hoʻomohala hou ʻana o nā mea hoʻohui polyamide / polyester a hoʻopili i nā hopena mua i ka hana hana maoli. Ma ka hoʻololiʻana i nā meaʻelua, loaʻa kahi mea hou e mālama ana i nā pono o nā meaʻelua. Loaʻa iā ia nā waiwai mechanical maikaʻi, ʻoi aku ka maikaʻi o ka pale wai ma mua o ka polyamide, a ʻoi aku ka paʻakikī o ka hopena ma mua o ka polyester. Hoʻohana nui ʻia ia i nā ʻoihana uila, uila a me nā ʻoihana automotive. palapala noi.

loulou i kēia ʻatikala: Ke ʻenehana hana ʻilikai e ʻike ʻia ai ka oka a ke alumini

Reprint Statement: Inā ʻaʻohe ʻōlelo aʻoaʻo kūikawā, kūmole nā ʻatikala āpau ma kēia pūnaewele. E ʻoluʻolu e kuhikuhi i ke kumu no ka paʻi hou ʻana: https: //www.cncmachiningptj.com/sthanks!

Hāʻawi ʻo PTJ® i kahi laulā o Precision Custom cnc craini china lawelawe.ISO 9001: 2015 & AS-9100 i hōʻoia ʻia. 3, 4 a me 5-axis ka wikiwiki wikiwiki CNC machining nā lawelawe e like me ka wili ʻana, huli i nā kikoʻī o ka mea kūʻai, Hiki i nā mea hao a me nā mīkini mīkini me +/- 0.005 mm ke ahonui. ʻO nā lawelawe ʻelua me ka CNC a me ka wili maʻamau, ʻeli ʻana.ke make,pepa hao a kauʻia.Hoʻolako i nā prototypes, nā hana hana holo piha, kākoʻo ʻenehana a me ka nānā piha ʻana kaʻa, aerospace, punahelu & hāmeʻa, alakaʻi kukui,'inikua, paikikala, a me ka mea kūʻai uilaʻoe nā ʻoihana. Ka lawe manawa ʻana. E haʻi iki iā mākou e pili ana i ka waihona kālā o kāu papahana a me ka manawa e manaʻo ʻia e hāʻawi ai. E hoʻolālā mākou me ʻoe e hoʻolako i nā lawelawe ʻoi aku ke kumukūʻai e kōkua iā ʻoe e hōʻea i kāu pahuhopu, Welina e kāhea iā mākou ( sales@pintejin.com ) pololei no kāu papahana hou.

Hāʻawi ʻo PTJ® i kahi laulā o Precision Custom cnc craini china lawelawe.ISO 9001: 2015 & AS-9100 i hōʻoia ʻia. 3, 4 a me 5-axis ka wikiwiki wikiwiki CNC machining nā lawelawe e like me ka wili ʻana, huli i nā kikoʻī o ka mea kūʻai, Hiki i nā mea hao a me nā mīkini mīkini me +/- 0.005 mm ke ahonui. ʻO nā lawelawe ʻelua me ka CNC a me ka wili maʻamau, ʻeli ʻana.ke make,pepa hao a kauʻia.Hoʻolako i nā prototypes, nā hana hana holo piha, kākoʻo ʻenehana a me ka nānā piha ʻana kaʻa, aerospace, punahelu & hāmeʻa, alakaʻi kukui,'inikua, paikikala, a me ka mea kūʻai uilaʻoe nā ʻoihana. Ka lawe manawa ʻana. E haʻi iki iā mākou e pili ana i ka waihona kālā o kāu papahana a me ka manawa e manaʻo ʻia e hāʻawi ai. E hoʻolālā mākou me ʻoe e hoʻolako i nā lawelawe ʻoi aku ke kumukūʻai e kōkua iā ʻoe e hōʻea i kāu pahuhopu, Welina e kāhea iā mākou ( sales@pintejin.com ) pololei no kāu papahana hou.

- 5 Hana Mahana Axis

- Cnc mīkini wili pōhaku

- Huli Cnc

- Nā Hana Hana

- ʻŌnaehana Machining

- ʻIlikai ʻili

- Mīkini Mīkini

- Mīkini Pahu

- Powder Metallurgy punahelu

- ʻO ka hoʻoholo

- Hale Hōʻikeʻike ʻĀpana

- Nā ʻĀpana Metal Auto

- Māhele Papa

- Heatsink LED

- Nā ʻĀpana Hale

- Nā ʻ Mobilepana Kelepona

- ʻĀpana Lapaʻau

- Nā ʻĀpana ʻEleʻele

- Mīkini hoʻopaʻa ʻia

- Nā Piʻi Bicycle

- Mīkini Aluminium

- Mīkini Titanium

- Mīkini kila

- Mīkini keleawe

- Mīkini Keleawe

- Hana Mīkini Hana Hou

- Mīkini peek

- UHMW mīkini

- Unilate mīkini

- PA6 mīkini

- PPS mīkini

- Mīkini ʻo Teflon

- Mīkini Inconel

- Mea Hana Pono Pono

- Nā Mea Hou