ʻO nā hopena o ka hoʻololi ʻana no ka CNC huli ʻana i nā ʻāpana ʻāpana-pā

I ke kaʻina o ka huli ʻana o CNC, ua hana pinepine ʻia kekahi mau ʻāpana ʻāpana lahilahi. I ka wā e hoʻohuli ai i nā mea hana pā lahilahi, ma muli o ka rigidity maikaʻi ʻole o ka mea hana, ʻo ka deformation o nā workpieces lahilahi-walled ma CNC lathes ʻo ia ka mea maʻamau i ka wā o ka huli ʻana.

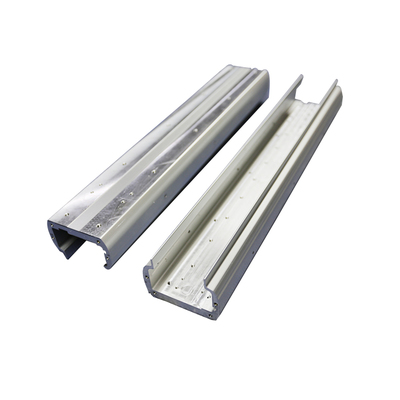

- 1. Ma muli o ka paia lahilahi o ka mea hana, ua maʻalahi ka deform ma lalo o ka hana o ka clamping pressure. Ma laila e pili ana i ka pololei o ke ana a me ka pololei o ke ʻano o ka mea hana. I ka hoʻohana ʻana i ka chuck ʻekolu-āwae e like me ka mea i hōʻike ʻia ma ke Kiʻi 1 e hoʻopaʻa i ka mea hana no ka hoʻoponopono ʻana i ka lua o loko, e lilo iki ia i triangle ma lalo o ka hana o ka ikaika clamping, akā loaʻa kahi puka cylindrical ma hope o ka hoʻohuli ʻana i ka lua. Ke hoʻokuʻu ʻia nā ʻauwae a wehe ʻia ka mea hana, e hoʻi ka pōʻai o waho i ke ʻano cylindrical ma muli o ka hoʻihoʻi ʻana o ka elastic, aʻo ka lua o loko e lilo i huinakolu ʻano arc e like me ia i hōʻike ʻia ma ke Kiʻi 2. Ke ana ʻana me kahi micrometer kūloko, ke anawaena. Ua like D ma na aoao a pau.

- 2. Ma lalo o ka hana o ka ʻoki ʻana (ʻoi aku ka ikaika o ka ʻoki radial), ua maʻalahi ka hana ʻana i ka vibration a me ka deformation, e pili ana i ka pololei o ke ana, ke ʻano, ka pololei o ke kūlana a me ka ʻili o ka ʻili o ka mea hana.

- 3. Ma muli o ka lahilahi o ka mea hana, ʻo ka wela o ka ʻoki ʻana e hana i ka deformation thermal o ka mea hana, kahi mea paʻakikī ke kāohi i ka nui o ka mea hana. No nā mea hana metala lahilahi me ka hoʻonui laina laina nui, e like me ka hoʻohuli mau ʻana i ka semi-finished a me ka hoʻopau ʻana i ka huli ʻana i hoʻokahi hoʻonohonoho ʻana, ʻo ka deformation thermal o ka mea hana i hana ʻia e ka wela o ka ʻoki ʻana e hoʻopilikia nui i kona kikoʻī, a i kekahi manawa e hana i ka mea hana. Paʻa i ka mea hoʻopaʻa.

Ua ʻike mākou i ke ʻano o ka hana ʻana o nā mea hana i hoʻopaʻa ʻia e ka CNC lathes, no laila he aha kā mākou e hana ai e pili ana i ka deformation o nā workpieces lahilahi-walled ma CNC lathes? Ua wehewehe ʻia kekahi mau haʻina ma lalo nei.

- 1. Hoʻokaʻawale ʻia ka mea hana i nā ʻāpana ʻōpala. I ka wā o ka hoʻohuli ʻino ʻana i ka pae huli ʻana, ma muli o ka ʻoki ʻoki nui ʻana, ʻoi aku ka nui o ka ikaika o ka hoʻopili ʻana, a ʻoi aku ka nui o ka deformation; i ka hoʻopau ʻana i ka huli ʻana, hiki ke liʻiliʻi iki ka ikaika clamping, a ma kekahi ʻaoʻao, ua deformed ka clamping. Ma ka ʻaoʻao ʻē aʻe, hiki iā ia ke hoʻopau i ka deformation i hoʻokumu ʻia e ka ikaika ʻoki nui i ka wā o ka huli ʻana.

- 2. I ka hoʻohana ʻana i nā ʻāpana geometric no ka hoʻohuli maikaʻi ʻana i nā mea hana i ka paia lahilahi, pono ke kiʻekiʻe o ka rigidity, ʻaʻole maʻalahi ka lōʻihi o ka wiper (maʻa mau 0.2-0.3mm), a ʻo ka ʻoki ʻoki e pono.

- 3. E hoʻonui i ka ʻili pili pili e like me ka mea i hōʻike ʻia ma ke Kiʻi 3. E hoʻohana i ka lima ʻāʻī a i ʻole kekahi mau ʻāwae palupalu kūikawā. Hoʻonui ʻia ka ʻili pili, no laila e māhele like ʻia ka ikaika clamping ma luna o ka mea hana, i ʻole e hoʻololi maʻalahi ka mea hana i ka wā o ka hoʻopili ʻana.

- 4. E ninini piha i ka wai ʻoki. Ma ka ninini piha ʻana i ka wai ʻoki, e hoʻemi i ka mahana ʻoki a hoʻemi i ka deformation thermal o ka mea hana.

- 5. Hoʻonui i nā iwi ʻaoʻao. Hana ʻia kekahi mau mea hana pā lahilahi me nā iwi ʻaoʻao he nui i ke kūlana paʻa e hoʻonui ai i ka rigidity ma ʻaneʻi, no laila e hana ka ikaika hoʻopili i nā iwi ʻaoʻao e hōʻemi i ka deformation o ka mea hana. Ma hope o ka pau ʻana o ka hana ʻana, wehe ʻia nā iwi ʻaoʻao. .

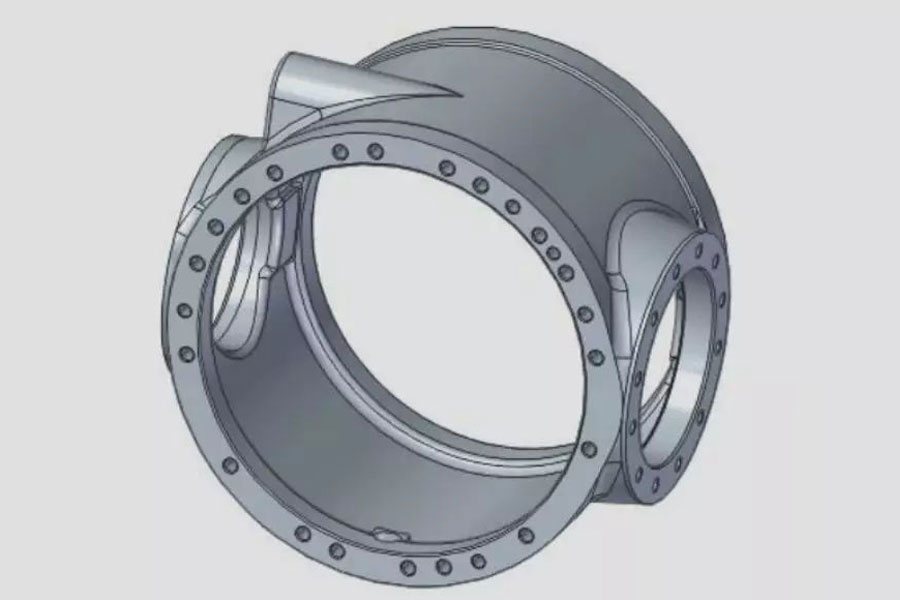

- 6. I ka axial clamping mea paʻa pono e hoʻohuli i nā mea hana pā lahilahi, ʻaʻole pono e hoʻohana ʻia ka radial clamping e like me ka hiki, a ʻoi aku ka maikaʻi o ke ʻano hoʻopili axial i hōʻike ʻia ma ke Kiʻi 4. Hoʻopili ʻia ka mea hana ma ka ʻaoʻao hope o ka lima hoʻopaʻa axial (lima kaula). Ma muli o ka māhele ʻia ʻana o ka ikaika clamping F ma ke ala axial o ka mea hana, nui ka rigidity axial o ka mea hana, a ʻaʻole maʻalahi ka hana ʻana i ka deformation clamping.

loulou i kēia ʻatikala:ʻO nā hopena o ka hoʻololi ʻana no ka CNC huli ʻana i nā ʻāpana ʻāpana-pā

Reprint Statement: Inā ʻaʻohe ʻōlelo aʻoaʻo kūikawā, kūmole nā ʻatikala āpau ma kēia pūnaewele. E ʻoluʻolu e kuhikuhi i ke kumu no ka paʻi hou ʻana: https: //www.cncmachiningptj.com/sthanks!

3, 4 a me 5-axis kikoʻī CNC machining nā lawelawe no mīkini aluminika, beryllium, hao kalapona, magnesium, mīkini titanium, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite a me ka lāʻau. Hiki iā ia ke hana i nā ʻāpana a hiki i ka 98 iniha. a me +/-0.001 in. ka hoʻomanawanui pololei. ʻO nā kaʻina hana e pili ana i ka wili, ka hoʻohuli ʻana, ka wili ʻana, ka luʻu ʻana, ka wili, ka paʻi ʻana, ka hana ʻana, ka knurling, ka counterboring, countersinking, reaming a me ka hana 'ana. Nā lawelawe lua e like me ka ʻākoakoa, wili waena, hoʻomehana wela, plating a me nā hao. Hāʻawi ʻia ka Prototype a haʻahaʻa a kiʻekiʻe me 50,000 mau ʻāpana. He kūpono no ka mana wai, pneumatics, hydraulics a me nohona kiwikā o nā noi. E lawelawe i ka aerospace, mokulele, pūʻali koa, lāʻau lapaʻau a me nā ʻoihana pale. E hoʻolālā pū ʻo PTJ me ʻoe e hāʻawi i nā lawelawe ʻoi aku ka maikaʻi loa e kōkua iā ʻoe e hōʻea i kāu pahuhopu, Welina e Hoʻokaʻaʻike mai iā mākou ( sales@pintejin.com ) pololei no kāu papahana hou.

3, 4 a me 5-axis kikoʻī CNC machining nā lawelawe no mīkini aluminika, beryllium, hao kalapona, magnesium, mīkini titanium, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite a me ka lāʻau. Hiki iā ia ke hana i nā ʻāpana a hiki i ka 98 iniha. a me +/-0.001 in. ka hoʻomanawanui pololei. ʻO nā kaʻina hana e pili ana i ka wili, ka hoʻohuli ʻana, ka wili ʻana, ka luʻu ʻana, ka wili, ka paʻi ʻana, ka hana ʻana, ka knurling, ka counterboring, countersinking, reaming a me ka hana 'ana. Nā lawelawe lua e like me ka ʻākoakoa, wili waena, hoʻomehana wela, plating a me nā hao. Hāʻawi ʻia ka Prototype a haʻahaʻa a kiʻekiʻe me 50,000 mau ʻāpana. He kūpono no ka mana wai, pneumatics, hydraulics a me nohona kiwikā o nā noi. E lawelawe i ka aerospace, mokulele, pūʻali koa, lāʻau lapaʻau a me nā ʻoihana pale. E hoʻolālā pū ʻo PTJ me ʻoe e hāʻawi i nā lawelawe ʻoi aku ka maikaʻi loa e kōkua iā ʻoe e hōʻea i kāu pahuhopu, Welina e Hoʻokaʻaʻike mai iā mākou ( sales@pintejin.com ) pololei no kāu papahana hou.

- 5 Hana Mahana Axis

- Cnc mīkini wili pōhaku

- Huli Cnc

- Nā Hana Hana

- ʻŌnaehana Machining

- ʻIlikai ʻili

- Mīkini Mīkini

- Mīkini Pahu

- Powder Metallurgy punahelu

- ʻO ka hoʻoholo

- Hale Hōʻikeʻike ʻĀpana

- Nā ʻĀpana Metal Auto

- Māhele Papa

- Heatsink LED

- Nā ʻĀpana Hale

- Nā ʻ Mobilepana Kelepona

- ʻĀpana Lapaʻau

- Nā ʻĀpana ʻEleʻele

- Mīkini hoʻopaʻa ʻia

- Nā Piʻi Bicycle

- Mīkini Aluminium

- Mīkini Titanium

- Mīkini kila

- Mīkini keleawe

- Mīkini Keleawe

- Hana Mīkini Hana Hou

- Mīkini peek

- UHMW mīkini

- Unilate mīkini

- PA6 mīkini

- PPS mīkini

- Mīkini ʻo Teflon

- Mīkini Inconel

- Mea Hana Pono Pono

- Nā Mea Hou