Make ʻo Carbide | Make nā Drawing | Make ʻo Tungsten Carbide | Hoʻomake loa | Make anu anuanu

ʻO Punch, puna, poʻo poʻo, extrusion, make ke kaha kiʻi: WE PTJ. KEKAHI O KA PALAPALA HOPE MA KINA KAI LOA

|

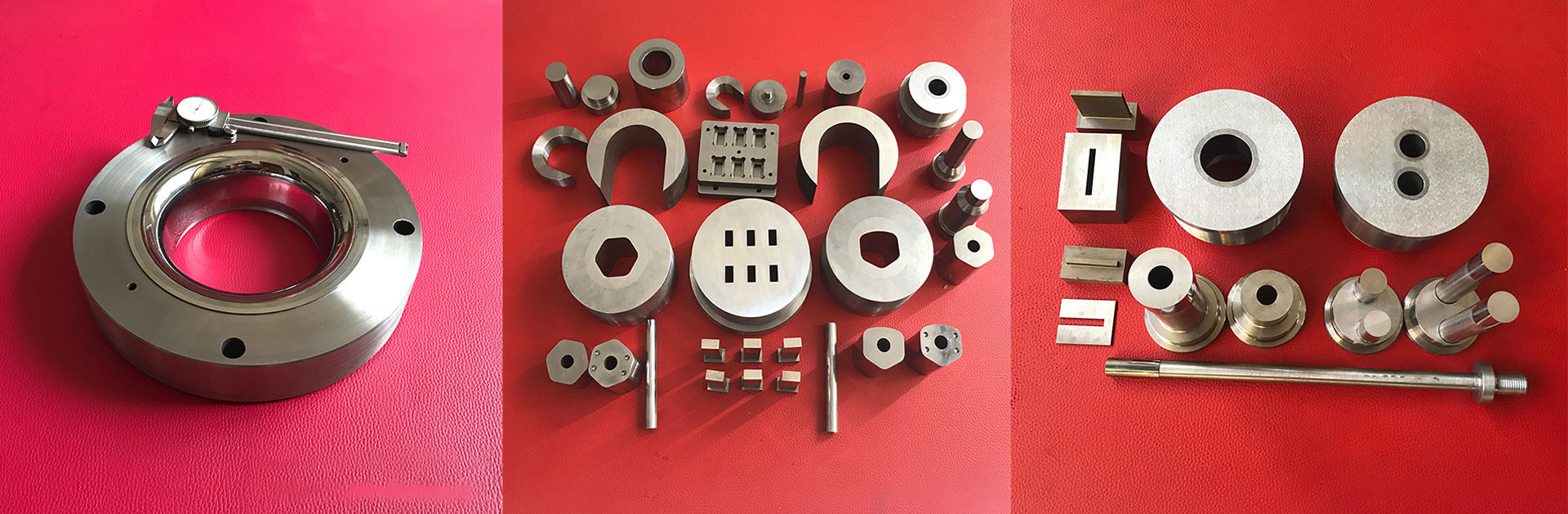

He aha ka make o carbide? ʻO ka make ʻo Carbide kahi ʻāpana nui o nā mea hana carbide sima. ʻO ka make ʻana o ka carbide sima i hoʻohana pinepine ʻia i ka make anuanu, make ka punching anuanu, make hexagonal, make spiral, a pēlā aku. Make ʻo Carbide he ʻumi mau manawa a ʻoi paha he mau manawa ka lōʻihi ma mua o ka make ʻana o ke kila. Make ʻo Tungsten carbide make i paʻakikī nui, ikaika kiʻekiʻe, kūpaʻa kūpale, kūpaʻa wela kiʻekiʻe a me ka coefficient hoʻonui hoʻonui. He mea nui ia i ka hana a me ka hana ʻana o ka carbide sima.

Ma ke ʻano he mea hana make china carbide make, Cold Forming Die, Drawing Die a me Carbide Extrusion Die ka loea o PTJ. Kūleʻa mākou i ka hana ʻana i ke kiʻekiʻena kikoʻī, hiki ke hoʻololi i ka hana pilikino kiʻekiʻe FESIALA Make ka magnet e hālāwai me ISO 9001: 2015 hōʻoia. Kāhea iā mā ou no kāu mau papahana.

Inā makemake ʻoe i nā huahana hopena maikaʻi i hana ʻia ma ke kumu kūʻai haʻahaʻa haʻahaʻa (ke kumukūʻai no kēlā me kēia ʻāpana a me nā keu ʻoi aku ka kiʻekiʻe), a laila makemake ʻoe e hana i kāu mea hao me ka PTJ. PTJ Make ʻo Carbide Mālama ka ʻoihana iā ʻoe i ke ahonui a me ka make lōʻihi lōʻihi - nā mea āpau me ke kumukūʻai haʻahaʻa a me ka lawe koke ʻana. ʻO ke kumu, me PTJ loaʻa iā ʻoe nā huahana kūpono ʻole a me ka lawelawe mea kūʻai aku mai nā loea make carbide maʻamau. E kiʻi i kahi ʻōlelo mai ka The Carbide Die Specialists i kēia lā! kāhea iā mā ˚ ou

|

|

|

|

|

|

|

|

leka mākou make ʻo carbide lawelawe nā mea hoʻokalakupua i kēia lā e kūkākūkā i nā kikoʻī o kāu papahana paʻakikī.

|

Hiki i ka PTJ Carbide Die Manufacturer ke hana i kāu mau make i kēlā me kēia papa helu carbide āu e kuhikuhi ai, akā naʻe, inā makemake ʻoe i kahi ʻōlelo aʻoi aku ka hauʻoli o kā mākou hui akamai e ʻōlelo aku iā ʻoe no ka papa hea e kūpono no kāu hana. ʻO kahi laʻana, e hāʻawi aku kekahi papa i nā ʻāpana kila kila ʻoi aku ka maikaʻi o ka hana ʻana o nā mea ʻē aʻe i ke keleawe. Hiki iā PTJ ke kālailai pehea e pau ai kou mau make a nānā i nā makahiki o ka ʻike e hōʻoia i ka pololei tungsten carbide nāu. Eia kekahi, e hana pū mākou me ʻoe e kālailai a hoʻopiha i kāu hana make ma o ka pane ʻana a me ka hoʻāʻo ʻana. Eia nā ʻoihana a me nā ʻaoʻao huahana a hiki iā mākou ke hana i nā make no ʻoe (note: make wale mākou, a ʻaʻohe o mākou hiki ke hana i nā huahana no ʻoe)

-

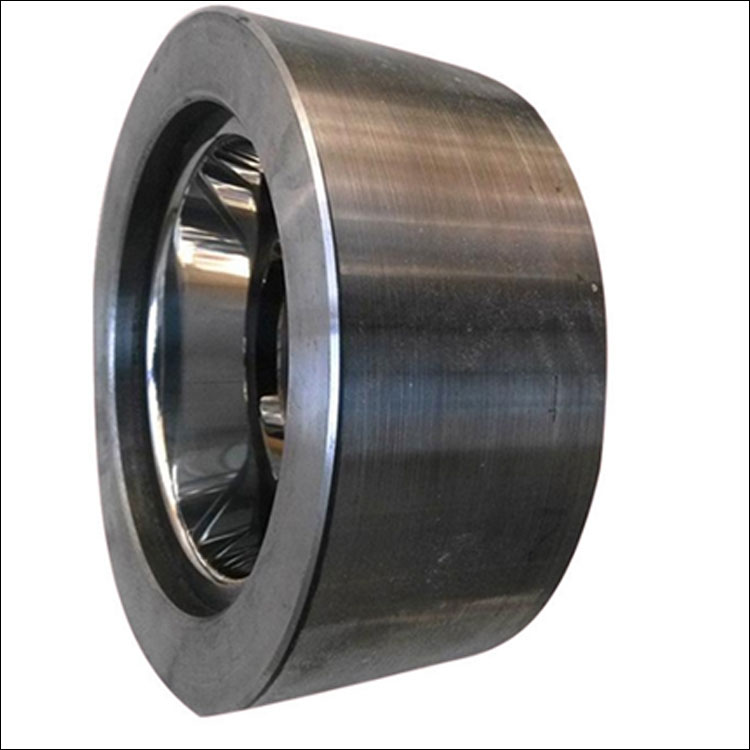

• Na apo Annular

-

• Pāleo Kinipōpō

-

• Nā lāʻau lāʻau

-

• ʻO Carbide Bushings

-

• Nā Hihia

-

• Nā pahi okioki

-

• Halawai Hewa

-

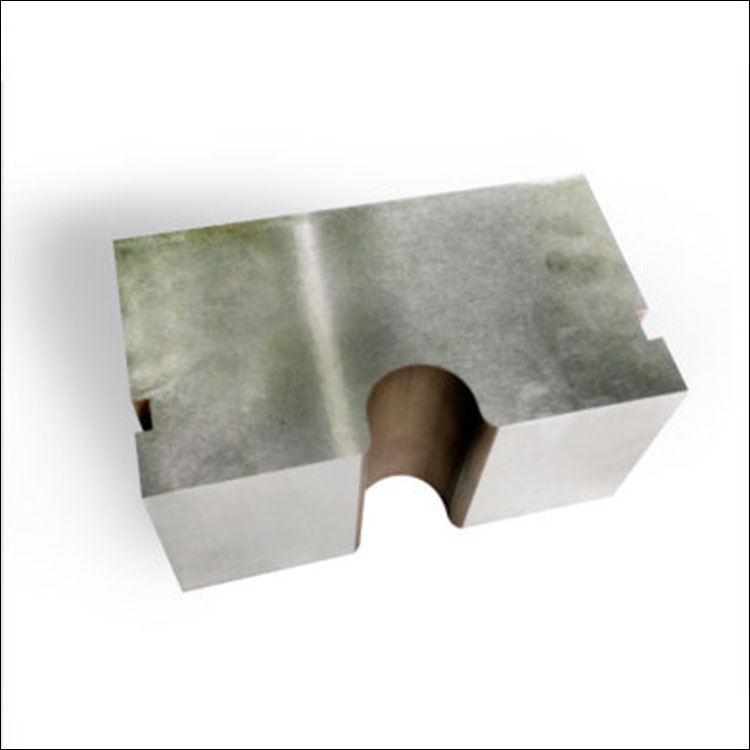

• nā poloka make

-

• Hoʻohuehue wili

-

• Nā Lola ʻAi

-

• Hoʻopiha

-

• Nā pale pale hex

-

• Hoʻokomo nā Carbide Die Inserts

-

• Mandrel

-

• Nibs

-

• Pin (Carbide)

-

• Make ʻo Carbide Point

-

• Ke hala nei ka hahi holomua

-

• Nā Hina Punch

-

• Nā Puni Carbide

-

• Nā kui

-

• Nā huaʻōlelo

-

• Extrusions kūikawā

-

• Make ke kaula wili

-

• nā manamana hoʻoili

-

• Extrusions hei

-

• Trilobes a me nā mea hou aku!

|

|

|

|

|

|

High pololei

|

Quote wikiwiki & lawelawe

|

Fast Delivery

|

Hoʻopau Dute

|

Nā Mīkini kikoʻī

|

Nā lawelawe hoʻohui

|

|

Make ka Classification o Carbide

|

Make pinepine ʻo Carbide: make ke poʻo anuanu, make ka punch anuanu, uea make ke kaha kiʻi ʻana, make hexagonal, make spiral, a pēlā aku.ʻO nā mākau a me nā ʻenehana hana o nā popo karbida: e like me nā mea maʻamau o ka mākeke YG3, YG6, YG6X, YG8, YG15, YG20, YG20C, YG25 a me HU20, HU222, HWN1 (puna non-magnet alloy ), a pēlā aku, me ka hoʻohana ʻana i nā mea carbide mua, kaomi haʻahaʻa E ʻoi aku ka ʻoi o ke kaʻina kūikawā e like me ka sinter ma mua o ka hana maʻamau, a hoʻonui ʻia ke ola lawelawe e 3-5 mau manawa. :

-

Ua make ke ʻano mua o ka uea i hoʻoheheʻe ʻia i ka uea, ʻo kēia ʻano o ka make e noho i ka hapa nui o nā make i hoʻoheheʻe ʻia. Ua make nā māka nui o ke kaha kiʻi uea ʻana i koʻu ʻāina ʻo YG8, YG6, YG3, a ukali ʻia e YG15, YG6X, YG3X, a ua hoʻomohala ʻia kekahi mau mana hou, e like me ka inoa ʻo YL hou no ke kaha kiʻi wikiwiki wikiwiki, a me ke kaha kiʻi uea make momi CS05 (YLO. 5) i lawe ʻia mai mai nā ʻāina ʻē. , CG20 (YL20), CG40 (YL30); K10, ZK20 / ZK30.

-

. ʻO ke ʻano ʻelua o ka punahelu ke poʻo anu, ke kuʻi anuanu a me nā kinikini. ʻO nā mana nui ʻo YC20C, YG20, YG15, CT35, YJT30 a me MO15.

-

.ʻO ke ʻano ʻekolu o ka punahelu he punahelu ʻume mākenēki ʻole ʻole i hoʻohana ʻia no ka hana ʻana i nā mea ʻume mākenēki, e like me YSN o ke kaʻina YSN (me 20, 25, 30, 35, 40) a me ka mea kila me ka papa hana non-magnet .

-

.Ua hana wela ka mahele ʻehā. ʻAʻohe papa maʻamau no kēia ʻano alloy, a ke piʻi nei ka noi mākeke.

|

|

|

|

Make Magnetic Flexible

|

Anuanu-Hoʻokumu-Make

|

Make ʻo Tungsten-Carbide

|

Kāpena-Punch

|

|

ʻO nā mea hana maʻamau no ka make ʻana o Carbide

|

Nui a hewahewa nā ʻano make o nā carbide me nā hana like ʻole, no laila he nui nā ʻano o nā mea i hoʻohana ʻia. Me ka hoʻomau mau ʻana o nā mea hou, hoʻomaikaʻi mau ʻia nā mea make. Wahi a nā ʻano hana ʻokoʻa, hiki ke hoʻokaʻawale ʻia nā mea make i: nā mea i hana ʻia e ka metala i ka mahana maʻamau (ke anuanu), i kapa ʻia anuanu e hana make ana kila; nā mea i hana ʻia ma lalo o ka mokuʻāina hoʻomehana, i kapa ʻia ka make hana carbide wela. I kēia manawa, ʻo nā mea i hoʻohana ʻia i ka make e komo pū me nā kila kila kila kila, nā kila hao mea hoʻoheheʻe kiʻekiʻe, nā hao kiʻekiʻe, nā hao hao, a me nā carbides FESIALA Mākēneki hikiwawe).

-

▶ ʻO ke kila kila kila ke kila kila kiʻekiʻe me kahi ʻona o 0.7% a 1.4%. ʻO nā papa nui nā T7, T7A, T8, T8A, T10, T12, T12A, a me nā mea ʻē aʻe. ʻO kēia ʻano mea kila he hana maikaʻi maikaʻi, kiʻekiʻe paʻakikī a me nā kūpaʻa maikaʻi ma hope o ke kinai ʻana, akā maikaʻi ʻole kona paʻakikī, pono e kinai ʻia i ka wā o ke kinai ʻana. , deformation and cracking tends to be big, tempering stable is poor, a haʻahaʻa thermal paakiki. He kūpono ia no ka hana ʻana i nā puna anuanu me ka liʻiliʻi a me ke ʻano maʻalahi.

-

▶ ʻO ke kila kila mea kila i hoʻoheheʻe ʻia e ka hoʻohui ʻana i hoʻokahi a i ʻole mau mea hoʻohui i ke kumu o ke kila kalapona. Hoʻohana mau ʻia nā mea hana kila carbide make i nā mea kila a me nā kila hana kila kiʻekiʻe.

-

▶ I kēia manawa, hoʻohana pinepine ʻia ke kila kila kiʻekiʻe (WC) W18Cr4V a me ka molybdenum kiʻekiʻe kiʻekiʻe (MoC) W6Mo5Cr4V2. ʻO ke kila wikiwiki ka maikaʻi o ka wikiwiki, hiki ke paʻakikī ʻia i ka lewa, a mālama mau i ka paʻakikī kiʻekiʻe, ikaika kiʻekiʻe, paʻakikī maikaʻi a paʻa i nā pale ma kahi o 600 ° C. Kūpono ke kila kila kiʻekiʻe no ka hana anuanu make ka extrusion.

|

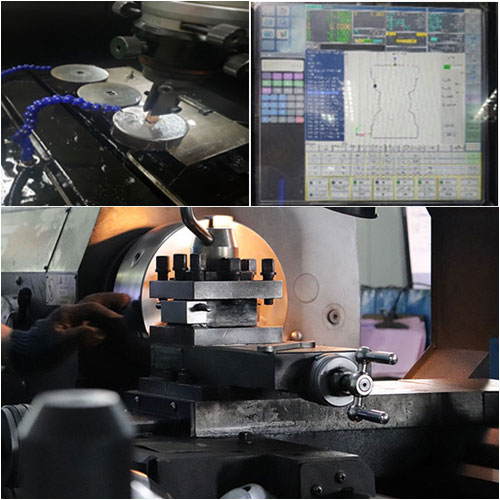

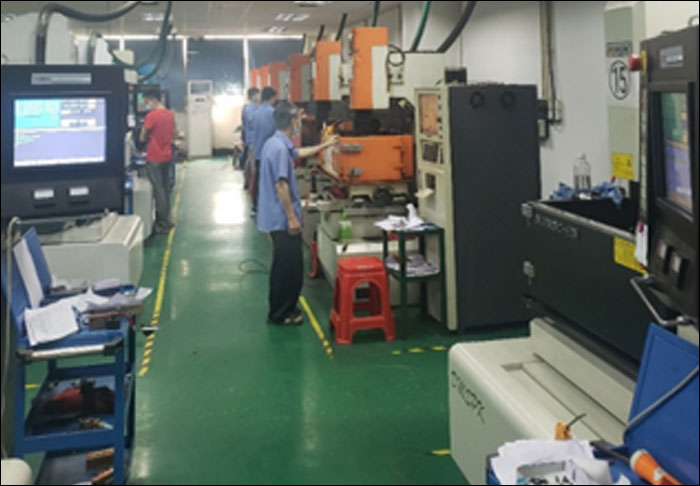

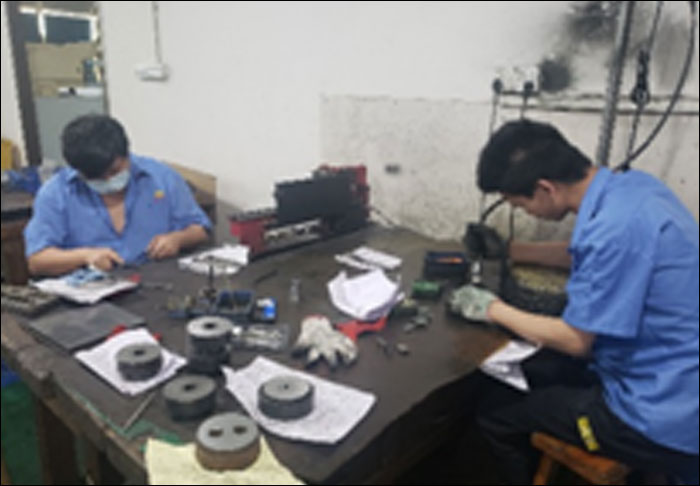

Make kā kā mākou Carbide a make i ke kaʻina hana ʻo Carbide

|

|

|

|

|

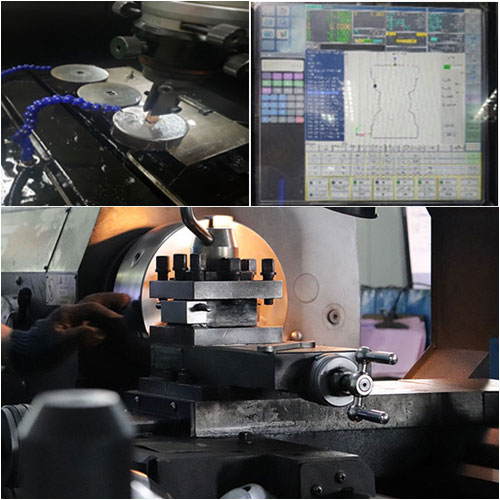

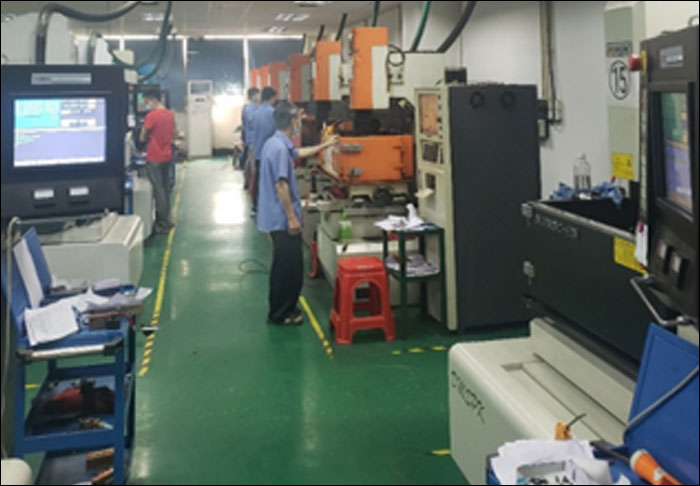

Mīkini EDM

|

Aaioee lathe nui

|

Ka wili ʻana a me ka anai ʻana

|

Komihana Hana

|

|

|

|

|

anai ana

|

Wili wili

|

Microscope ʻoihana

|

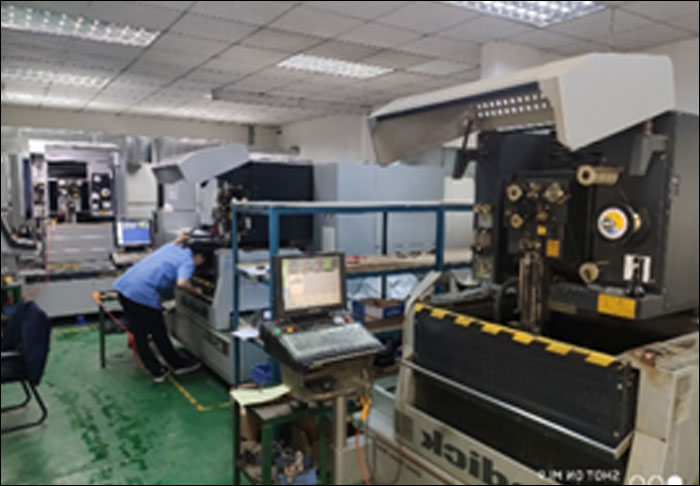

Mīkini uea lohi

|

MAKE ʻO CARBIDE I NĀ KULA NĀ KAHI

E ʻike i nā ʻenehana mīkini hou aʻe ma kā mākou ʻAoʻao Gallery

Ke lawelawe nei ʻo PTJ i nā mea kūʻai aku ma ka honua holoʻokoʻa mai ka makahiki 2007. Mālama mau mākou i ko mākou mākau a hoʻomaikaʻi i kā mākou lako pono e ʻike pono e māʻona kā mākou mea kūʻai aku. Nui mākou i nā mea kūʻai aku kūpaʻa i hana pū me mākou no 10 mau makahiki. E nānā i nā ʻenehana mīkini ʻē aʻe a aʻo hou i ka calture e pili ana i ka PTJ Lako paʻa.